1) Num duritiem probans Rockwell adhiberi potest ad duritiem parietis tubi ferrei explorandam?

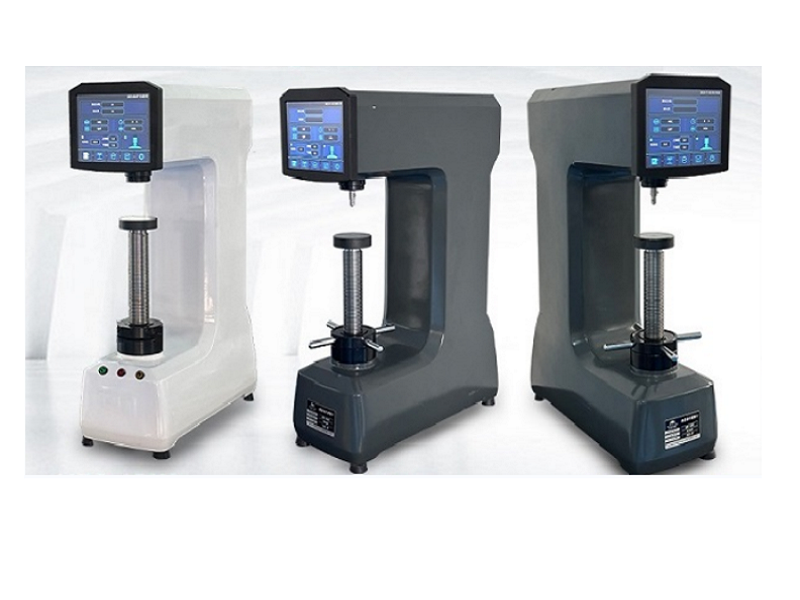

Materia probationis est tubus chalybis SA-213M T22, diametro externo 16 mm et crassitudine parietis 1.65 mm. Resultata probationis duritiei Rockwellianae haec sunt: Post remotionem oxidi et strati decarburati e superficie speciminis cum mola, specimen in mensa laboris formae V positum est et probatio duritiei Rockwelliana directe in superficie externa peracta est, utens duritiei Rockwellianae probatore cum ostensione digitali HRS-150S, onere 980.7 N.

Post experimentum, videri potest tubum ferreum in pariete leviter deformatum esse, et eventus est: humilis valor duritiae Rockwell mensuratus experimentum invalidum reddit.

Secundum GB/T 230.1-2018 « Examen duritiae Rockwell pro materiis metallicis Pars 1: Methodi probationis », duritia Rockwell est 80HRBW et crassitudo minima speciminis est 1.5 mm. Crassitudo speciminis No. 1 est 1.65 mm, crassitudo strati decarburati est 0.15~0.20 mm, et crassitudo speciminis post remotionem strati decarburati est 1.4~1.45 mm, quae crassitudini minimae speciminis in GB/T 230.1-2018 specificatae prope est.

Inter experimentum, quia centrum exempli non sustentatur, deformatio levis (fortasse oculo nudo invisibilis) fiet, itaque valor duritiae Rockwell mensuratus satis humilis est.

2) Quomodo superficiale eligendum sitRockwellduritiem probantem ad tubos ferreos examinandos:

Societas nostra duritiem superficiei tubi ferrei iterum atque iterum probavit et ad sequentes conclusiones pervenit:

Examen duritiae Rockwell superficialis vel examen duritiae Rockwell in superficie tubi chalybei tenuibus parietibus. Sustentatio parietis insufficiens deformationem speciminis causabit et eventus probationis humiles afferet;

Si fulcrum cylindricum in medio tubi ferrei tenuis parietis ponitur, quia axis indentationis et directio oneris necnon superficies tubi ferrei perpendicularis superficiei esse non potest, et superficies exterior tubi ferrei hiatus inter superficiem circularem tubi ferrei et superficiem fulcri cylindrici efficietur, quod etiam eventum probationis satis humilem efficiet.

Converte probationem duritiae Vickers in probationem duritiae Rockwell post polituram inserti exemplaris tubi ferrei, valorem duritiae Rockwell satis accuratum habebis.

2. Post remotionem oxidi et strati decarburizationis e superficie tubi ferrei et machinationem plani probationis in superficie externa et insertionem eius, Value accuratior est comparatus cum probatore duritiei Rockwell superficiali cum probatore duritiei Rockwell.

Tempus publicationis: XXVIII Maii, MMXXIV