Durities in loco circa suturam adiuvare potest ad fragilitatem suturae aestimandam, ita adiuvans te ad determinandum utrum sutura robur requisitum habeat, ergo methodus probationis duritiae Vickers suturae est methodus quae adiuvat ad qualitatem suturae aestimandam.

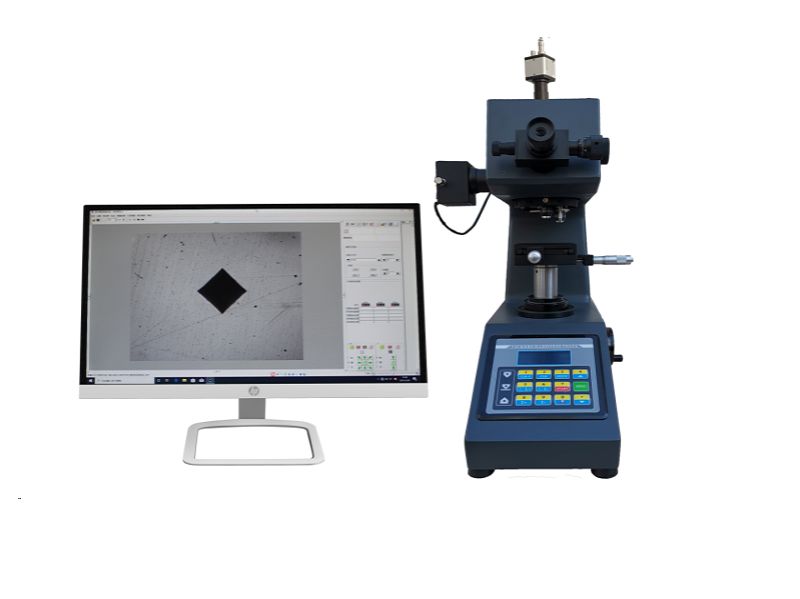

Instrumentum probationis Vickers societatis Shandong Shancai /Laizhou Laihua potest probationem duritiei in partibus conglutinatis vel locis conglutinatis perficere. Cum duritia puncti conglutinati probatur, mensurae multipunctales fiunt ad certam distantiam a margine exemplaris vel a summo puncti conglutinati. Postquam indentatio multipunctalis obtenta est, valor duritiei mensura continua metiri potest et graphum curvae obtineri potest.

Cum instrumento Vickers ad partes conglutinatas examinandas uteris, hae condiciones probationis notandae sunt:

1. Planities exempli: Ante probationem, suturam probandam deterimus ut superficies eius laevis sit, libera strato oxidi, fissuris aliisque defectibus.

2. In linea media suturae, punctum in superficie curva singulis 100 mm ad probationem sume.

3. Eligendo vires probationis diversas eventus diversos habebimus, ergo vim probationis aptam ante probationem eligere debemus.

Instrumentum microduritatis requisita habet pro finitione superficiali exemplaris examinati, quae diligenter secundum exemplar metallographicum praeparanda est.

Principium probationis microduritatis in methodo probationis microduritatis prorsus idem est ac duritia Vickers, sed onus adhibitum minus est quam duritia Vickers oneris parvi, plerumque minus quam 1000g, et indentatio inderigens est tantum pauca micron ad pauca duo micron, ita probatio microduritatis modum percommodum praebet ad proprietates microstructurae strati permeabilis investigandas. Late adhibetur ad duritiam cuiusque phasis in superficie et in strato permeante determinandam.

Symbolum microduritatis plerumque per HV exprimitur, et principium determinationis eius ac methodus similia sunt methodo duritiae Vickersianae. Systema onerandi, systema mensurandi et praecisio indentationis probatoris microduritatis magis exigentia sunt quam probatoris duritiae Vickersiani sub onere humili. Hodie, probator microduritatis late in tenuibus operibus adhibetur, et quia amplificatio quadringentas vicibus attingere potest, saepe ut simplex microscopium metallographicum adhibetur.

In usu, onus, micrometrum et indentarium probatoris microduritiei attendendum est, quae ante usum inspicienda sunt, et quadratum duritiae ad plenam identificationem valoris indicativi adhibendum est.

Instrumentum ad microduritiem examinandam onus in operatione examinationis quam levissime et aequabiliter adhibet, sine ictu et vibratione. Ut accuratio eventuum examinationis confirmetur, plerumque necesse est pluries in diversis partibus metiri, et valorem medium invenire qui valorem duritiei strati examinationis permeabilitatis vel phasis mixturae repraesentat. Pro strato infiltrationis ad altam temperaturam adhibito, eius durities instrumento ad microduritiem examinandam ad altam temperaturam metiri potest.

Tempus publicationis: Apr-10-2024